Rolf Engg. Solutions Inc is the largest stockist and supplier of API 5l PSL 2 Pipes from Grade B to X120. We stock pipes of Japan, Europe, Korea, China, India origin. We also have stocks of Sour Service, HIC Tested, NACE MR 0175/0103, SSC Tested material.

Our Stock range consists of:

Seamless Pipes - 1/2" to 42"

ERW Pipes - 1/2" to 24"

LSAW Pipes - 20" to 100"

Thickness - Sch 10 to Sch XXS and heavier.

For different environment there will be different requirement for API 5L line Pipes. The PSL 2 Line Pipes contains additional chemical, mechanical properties and testing requirement. This specification covers seamless and welded steel line pipe from grades B through X80. API 5L Line Pipes can be supplied in Normalized condition, Quenched and Tempered Condition and also in Mechanical conditions. If you require PSL 2 pipes means these pipes are used for natural gas pipe or crude oil line pipe where there are high requirements for pipe pressure, pipe anti-corrosion ability, high mechanical strength etc.

We can export and supply

API 5L Grade B PSL2, API 5L X42 PSL2, API 5L X46 PSL2, API 5L X52 PSL2, API 5L X56 PSL2, API 5L X60 PSL2, API 5L X65 PSL2, API 5L X70 PSL2, API 5L X80 PSL2, API 5L L245R PSL2 or API 5L BR PSL2, API 5L L290R PSL2 or API 5L X42R PSL2, API 5L L245N PSL2 or API 5L BN PSL2, API 5L L290N PSL2 or API 5L X42N PSL2, API 5L L320N PSL2 or API 5L X46N PSL2, API 5L L360N PSL2 or API 5L X52N PSL2, API 5L L390N PSL2 or API 5L X56N PSL2, API 5L L415N PSL2 or API 5L X60N PSL2, API 5L L245Q PSL2 or API 5L BQ PSL2, API 5L L290Q PSL2 or API 5L X42Q PSL2, API 5L L245Q PSL2 or API 5L BQ PSL2, API 5L L290Q PSL2 or API 5L X42Q PSL2, API 5L L320Q PSL2 or API 5L X46Q PSL2, API 5L L360Q PSL2 or API 5L X52Q PSL2, API 5L L390Q PSL2 or API 5L X56Q PSL2, API 5L L415Q PSL2 or API 5L X60Q PSL2, API 5L L450Q PSL2 or API 5L X65Q PSL2, API 5L L485Q PSL2 or API 5L X70Q PSL2, API 5L L555Q PSL2 or API 5L X80Q PSL2, API 5L L245M PSL2 or API 5L BM PSL2, API 5L L290M PSL2 or API 5L X42M PSL2, API 5L L320M PSL2 or API 5L X46M PSL2, API 5L L360M PSL2 or API 5L X52M PSL2, API 5L L390M PSL2 or API 5L X56M PSL2, API 5L L415M PSL2 or API 5L X60M PSL2, API 5L L450M PSL2 or API 5L X65M PSL2, API 5L L485M PSL2 or API 5L X70M PSL2, API 5L L555M PSL2 or API 5L X80M PSL2, API 5L L625M PSL2 or API 5L X90M PSL2, API 5L L690M PSL2 or API 5L X100M PSL2, API 5L L830M PSL2 or API 5L X120M PSL2.

| API 5L L245R PSL2 or API5L PSL2 BR | API 5L L290R PSL2 or API5L PSL2 X42R | API 5L L245N PSL2 or API5L PSL2 BN |

| API 5L L290N PSL2 or API5L PSL2 X42N | API 5L L320N PSL2 or API5L PSL2 X46N | API 5L L360N PSL2 or API5L PSL2 X52N |

| API 5L L390N PSL2 or API5L PSL2 X56N | API 5L L415N PSL2 or API5L PSL2 X60N | API 5L L245Q PSL2 or API5L PSL2 BQ |

| API 5L L245Q PSL2 or API5L PSL2 BQ | API 5L L290Q PSL2 or API5L PSL2 X42Q | API 5L L320Q PSL2 or API5L PSL2 X46Q |

| API 5L L360Q PSL2 or API5L PSL2 X52Q | API 5L L390Q PSL2 or API5L PSL2 X56Q | API 5L L415Q PSL2 or API5L PSL2 X60Q |

| API 5L L450Q PSL2 or API5L PSL2 X65Q | API 5L L485Q PSL2 or API5L PSL2 X70Q | API 5L L555Q PSL2 or API5L PSL2 X80Q |

| API 5L L245M PSL2 or API5L PSL2 BM | API 5L L290M PSL2 or API5L PSL2 X42M | API 5L L320M PSL2 or API5L PSL2 X46M |

| API 5L L360M PSL2 or API5L PSL2 X52M | API 5L L390M PSL2 or API5L PSL2 X56M | API 5L L415M PSL2 or API5L PSL2 X60M |

| API 5L L450M PSL2 or API5L PSL2 X65M | API 5L L485M PSL2 or API5L PSL2 X70M | API 5L L555M PSL2 or API5L PSL2 X80M |

| API 5L L625M PSL2 or API5L PSL2 X90M | API 5L L690M PSL2 or API5L PSL2 X100M | API 5L L830M PSL2 or API5L PSL2 X120M |

Chemical composition for PSL 2 pipe with t ≤ 25,0 mm (0.984 in) (As per API 5L 45th Edition)

API 5L Steel Grade (Steel Name) |

Mass Fraction, Based Upon Heat and Product Analysis a

% Maximum |

Carbon Equivalent a % Maximum |

|||||||||

C b |

Si |

Mn b |

P |

S |

V |

Nb |

Ti |

Other |

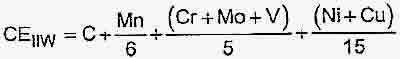

CE IIW |

CE PCM |

|

Seamless and Welded Pipe |

|||||||||||

| L245R or BR | 0,24 |

0,40 |

1,20

|

0,025

|

0,015

|

c

|

c |

0.04 |

e,l

|

0,43

|

0,25

|

| L290R or X42R | 0,24 |

0,40 |

1,20

|

0,025

|

0,015 |

0,06 |

0,05 |

0.04 |

e,l |

0,43 |

0,25 |

| L245N or BN | 0,24 |

0,40 |

1,20

|

0,025

|

0,015 |

c |

c |

0.04 |

e,l |

0,43 |

0,25 |

| L290N or X42N | 0,24 |

0,40 |

1,20

|

0,025

|

0,015 |

0,06 |

0,05 |

0.04 |

e,l |

0,43 |

0,25 |

| L320N or X46N | 0,24 |

0,40 |

1,40

|

0,025

|

0,015 |

0,07 |

0,05 |

0.04 |

d,e,l |

0,43 |

0,25 |

| L360N or X52N | 0,24 |

0,45 |

1,40

|

0,025

|

0,015 |

0,10 |

0,05 |

0.04 |

d,e,l |

0,43 |

0,25 |

| L390N or X56N | 0,24 |

0,45 |

1,40

|

0,025

|

0,015 |

0,10 f |

0,05 |

0.04 |

d,e,l |

0,43 |

0,25 |

| L415N or X60N | 0,24 f |

0,45 f |

1,40 f

|

0,025

|

0,015 |

0,10 f |

0,05 f |

0.04 f |

g,h,l |

as agreed |

|

| L245Q or BQ | 0,18 |

0,45 |

1,40

|

0,025

|

0,015 |

0,05 |

0,05 |

0.04 |

e,l |

0,43 |

0,25 |

| L290Q or X42Q | 0,18 |

0,45 |

1,40

|

0,025

|

0,015 |

0,05 |

0,05 |

0.04 |

e,l |

0,43 |

0,25 |

| L320Q or X46Q | 0,18 |

0,45 |

1,40 |

0,025 |

0,015 |

0,05 |

0,05 |

0.04 |

e,l |

0,43 |

0,25 |

| L360Q or X52Q | 0,18 |

0,45 |

1,50 |

0,025 |

0,015 |

0,05 |

0,05 |

0.04 |

e,l |

0,43 |

0,25 |

| L390Q or X56Q | 0,18 |

0,45 |

1,50 |

0,025 |

0,015 |

0,07 |

0,05 |

0.04 |

d,e,l |

0,43 |

0,25 |

| L415Q or X60Q | 0,18 f |

0,45 f |

1,70 f |

0,025 |

0,015 |

g |

g |

g |

h,l |

0,43 |

0,25 |

| L450Q or X65Q | 0,18 f |

0,45 f |

1,70 f |

0,025 |

0,015 |

g |

g |

g |

h,l |

0,43 |

0,25 |

| L485Q or X70Q | 0,18 f |

0,45 f |

1,80 f |

0,025 |

0,015 |

g |

g |

g |

h,l |

0,43 |

0,25 |

| L555Q or X80Q | 0,18 f

|

0,45 f |

1,90 f

|

0,025 |

0,015 |

g |

g |

g |

i,j |

as agreed |

|

| L625Q or X90Q | 0,16 f

|

0,45 f |

1,90

|

0,020 |

0,010 |

g |

g |

g |

j,k |

as agreed |

|

| L690Q or X100Q | 0,16 f

|

0,45 f |

1,90

|

0,020 |

0,010 |

g |

g |

g |

j,k |

as agreed |

|

Welded Pipe |

|||||||||||

| L245 or BM | 0,22 |

0,45 |

1,20 |

0,025 |

0,015 |

0,05 |

0,05 |

0,04 |

e,l |

0,43 |

0,25 |

| L290M or X42M | 0,22 |

0,45 |

1,30 |

0,025 |

0,015 |

0,05 |

0,05 |

0,04 |

e,l |

0,43 |

0,25 |

| L320M or X46M | 0,22 |

0,45 |

1,30 |

0,025 |

0,015 |

0,05 |

0,05 |

0,04 |

e,l |

0,43 |

0,25 |

| L360M or X52M | 0,22 |

0,45 |

1,40 |

0,025 |

0,015 |

d |

d |

d |

e,l |

0,43 |

0,25 |

| L390M or X56M | 0,22 |

0,45 |

1,40 |

0,025 |

0,015 |

d |

d |

d |

e,l |

0,43 |

0,25 |

| L415M or X60M | 0,12 f |

0,45 f |

1,60 f |

0,025 |

0,015 |

g |

g |

g |

h,l |

0,43 |

0,25 |

| L450M or X65M | 0,12 f |

0,45 f |

1,60 f |

0,025 |

0,015 |

g |

g |

g |

h,l |

0,43 |

0,25 |

| L485M or X70M | 0,12 f |

0,45 f |

1,70 f |

0,025 |

0,015 |

g |

g |

g |

h,l |

0,43 |

0,25 |

| L555M or X80M | 0,12 f |

0,45 f |

1,85 f |

0,025 |

0,015 |

g |

g |

g |

i,l |

0,43 f |

0,25 |

| L625M or X90M | 0,10 |

0,55 f |

2,10 f |

0,020 |

0,015 |

g |

g |

g |

i,l |

-- |

0,25 |

| L690M or X100M | 0,10 |

0,55 f |

2,10 f |

0,020 |

0,010 |

g |

g |

g |

i,j |

0,25 |

|

| L830M or X120M | 0,10 |

0,55 f |

2,10 f |

0,020 |

0,010 |

g |

g |

g |

i,j |

0,25 |

|

a Based upon product analysis. For seamless pipe with t > 20,0 mm (0.787 in), the CE limits shall be as agreed.

The CEiiw limits apply if C > 0,12 % and the CEpcm limits apply if the C ≤ 0,12 %.

b For each reduction of 0,01 % below the specified maximum for C, an increase of 0,05 % above the specified maximum for Mn is permissible, up to a maximum of 1,65 % for grades ≥ L245 or B, but ≤ L360 or X52; up to a maximum of 1,75 % for

grades > L360 or X52,

but < L485 or X70; up to a maximum of 2,00 % for grades ≥L485 or X70, but ≤ L555 or X80; and up to a

maximum of 2,20 % for grades >L555 or X80.

c Unless otherwise agreed , Nb + V ≤ 0,06 %.

d Nb + V + Ti ≤ 0,15 %.

e Unless otherwise agreed, Cu ≤ 0,50 %; Ni ≤ 0,30 %; Cr ≤ 0,30 %; Mo ≤ 0,15 %.

f Unless otherwise agreed.

g Unless otherwise agreed, Nb + V + Ti ≤ 0,15 %.

h Unless otherwise agreed, Cu ≤ 0,50 %; Ni ≤ 0,50 %; Cr ≤ 0,50 %; Mo ≤ 0,50 %.

i Unless otherwise agreed, Cu ≤ 0,50 %; Ni ≤ 1,00 %; Cr ≤ 0,50 %; Mo ≤ 0,50 %.

j B ≤ 0,004 %.

k Unless otherwise agreed, Cu ≤ 0,50 %; Ni ≤ 1,00 %; Cr ≤ 0,55 %; Mo ≤ 0,80 %.

l For all PSL 2 pipe grades except those to which footnote j already applies, the following applies. Unless otherwise agreed no intentional addition of B is permitted and residual B ≤ 0,001 %.

9.2 Chemical compostion

9.2.2 For PSL 2 pipe with t ≤ 25,0 mm (0.984 in) the chemical composition for standard grades shall be as given in Table above and for intermediate grades shall be as agreed, but consistent with those given in Table

9.2.4 For PSL 2 pipe with a product analysis carbon mass fraction equal to or less than 0,12 %, the carbon equivalent, CEpcm, shall be determined

using Equation (2):

![]()

where the symbols for the chemical elements represent the mass fraction in percent (see Table above).

.If the heat analysis for boron is less than 0,000 5 % then it is not necessary for the product analysis to include boron, and the boron

content may

be considered to be zero for the CEpcm calculation.

9.2.5 For PSL 2 pipe with a product analysis carbon mass fraction greater than 0,12 % the carbon equivalent, CEllw shall be

determined using Equation (3):

where the symbols for the chemical elements represent the mass fraction in percent (see Table above).

NOTE: A derogation from the ISO rules for the presentation of chemical equations has been granted for Equations (2) and (3) in

deference to

their longstanding use in the industry.

Requirements for the results of tensile tests for PSL 2 pipe

API 5L Steel Grade |

Pipe Body of Seamless and Welded Pipes

|

Weld Seam of HFW, SAW and COW Pipes |

|||||

Yield Strength.a |

Tensile Strength.a |

Ration a, b, c Rt0,5 / Rm |

Elongation |

Tensile Strength.d |

|||

Minimum |

Maximum |

Minimum |

Maximum |

Maximum |

Minimum |

Minimum |

|

| L245R or BR L245N or BN L245Q or BQ L245M or BM |

245 (35 500) |

450 e (65 300) e |

415 (60 200) |

655 (95 000) |

0.93 |

f |

415 (60 200) |

| L290R or X42R L290N or X42N L290Q or X42Q L290M or X42M |

290 (42 100) |

495 (71 800) |

415 (60 200) |

655 (95 000) |

0.93 |

f |

415 (60 200) |

| L320N or X46N L320Q or X46Q L320M or X46M |

320 (46 400) |

525 (76 100) |

435 (63 100) |

655 (95 000) |

0.93 |

f |

435 (63 100) |

| L360N or X52N L360Q or X52Q L360M or X52M |

360 (52 200) |

530 (76 900) |

460 (66 700) |

760 (110 200) |

0.93 |

f |

460 (66 700) |

| L390N or X56N L390Q or X56Q L390M or X56M |

390 (56 600) |

545 (79 000) |

490 (71 100) |

760 (110 200) |

0.93 |

f |

490 (71 100) |

| L415N or X60N L415Q or X60Q L415M or X60M |

415 (60 200) |

565 (81 900) |

520 (75 400) |

760 (110 200) |

0.93 |

f |

520 (75 400) |

| L450Q or X65Q L450Q or X65M |

450 (65 300) |

600 (87 000) |

535 (77 600) |

760 (110 200) |

0.93 |

f |

535 (77 600) |

| L485Q or X70Q L485Q or X70M |

485 (70 300) |

635 (92 100) |

570 (82 700) |

760 (110 200) |

0.93 |

f |

570 (82 700) |

| L555Q or X80Q L555Q or X80M |

555 (80 500) |

705 (102 300) |

625 (90 600) |

825 (119 700) |

0.93 |

f |

625 (90 600) |

| L625M or X90M | 625 (90 600) |

775 (112 400) |

695 (100 800) |

915 (132 700) |

0.95 |

f |

695 (100 800) |

| L625Q or X90Q | 625 (90 600) |

775 (112 400) |

695 (100 800) |

915 (132 700) |

0.97 g |

f |

- |

| L690M or X100M | 690 b (100 100)b |

840b (121 800)b |

760 (110 200) |

990 (143 600) |

0.97 h |

f |

760 (110 200) |

| L690Q or X100Q | 690 b (100 100)b |

840b (121 800)b |

760 (110 200) |

990 (143 600) |

0.97 h |

f |

- |

| L830M or X120M | 830 b (120 400)b |

1050 b (152 300)b |

915 (132 700) |

1145 (166 100) |

0.99 h |

f |

915 (132 700) |

a For intermediate grades, the difference between the specified maximum yield strength and the specified minimum yield strength shall be as given in the table for the next higher grade, and the difference between the specified minimum tensile strength and the specified minimum yield strength shall be as given in the table for the next higher grade, For intermediate gradesup tp Grade L320 or X46, the tensile strength shall be ≤ 655 MPa (95 000 psi). For intermediate grades greater than Grade L320 or X46 and lower than Grade L555 or X80, the tensile strength shall be ≤ 760 MPa (110 200 psi). For intermediate grades higher than Grade L555 or X80, the maximum permissible tensile strength shall be obtained by interpolation. For SI units, the calculated value shall be rounded to the nearest 5 MPa. For USC units, the calculated value shall be rounded to the nearest 100 psi.

b For grades >L625 or X90, Rp0,2 applies.

c This limit applies for pipe with D >323, 9 mm (12.750 in).

d For intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determined for the pipe body using footnote a).

e For pipe requiring longitudinal testing, the maximum yield strength shall be ≤ 495 MPa (71 800 psi).

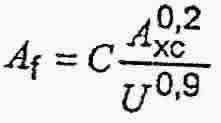

f The specified minimum elongation, Af, shall be as determined using the following equation:

Where

C is 1 940 for calculations using SI units and 625 000 for calculations using USC units;

A xc is the applicable tensile test piece cross-sectional area, expressed in square millimeters (square inches), as follows:

--- for circular cross-section test pieces, 130 mm2 (0.20 in2) for 12,5 mm (0.500 in) and 8,9 mm (0.350 in) diameter test pieces; and 65 mm2 ( 0.10 in2) for 6,4 mm (0.250 in) diameter test pieces;

--- for full-section test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified outside diameter and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.01 in2)

--- for strip test pieces, the lesser of a) 485 mm2 (0.75 in2 ) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe, rounded to the nearest_10 mm2 (0.01 in2 );

U is the specified minimum tensile strength, expressed in megapascals (pounds per square inch).

g Lower values of Rto,5/Rm may be specified by agreement.

h For grades > L625 or X90, Rp0,2/Rm applies. Lower values of Rp0,2/Rm may be specified by agreement.